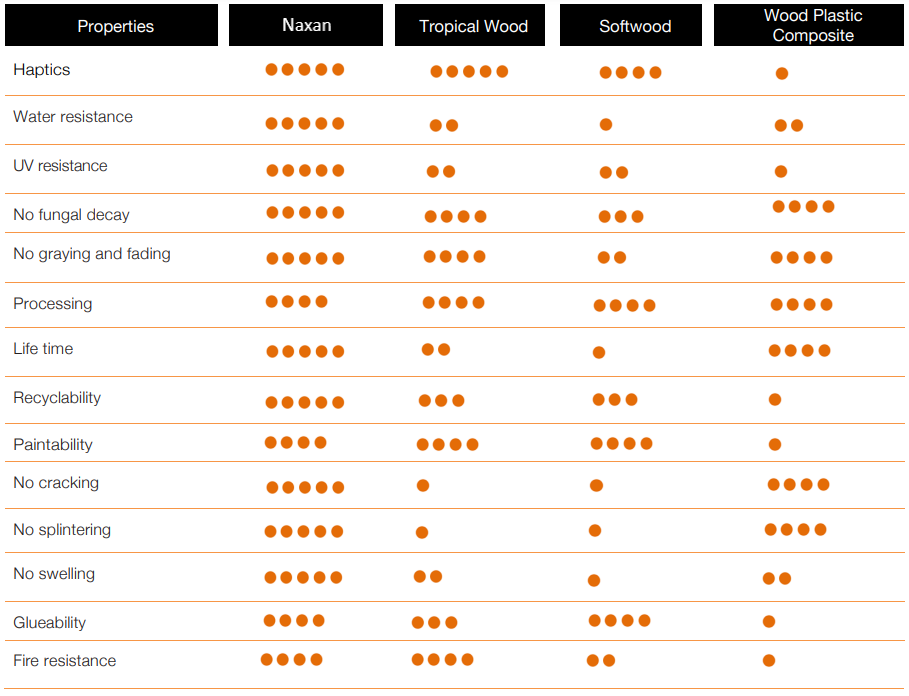

Timber, Wood Plastic Composite, and Naxan Comparison

Teak Timber, WPC and Naxan after 2000h.

There are many considerations when choosing the perfect material for your project. Naxan has an advantage in many fronts over other options such as timber and other composite materials on the market. We will go over some of the ones we consider of vital importance (maintenance requirements, environmental impact, livability and cost) to showcase the value proposition of our product Naxan.

Lightweight, easy and quick to install. Pre-finished with rich textures for design and aesthetic variations. Eco-friendly, durable, energy saving, low-maintenance and recyclable.

Maintenance

Naxan: Little-to-no maintenance required. No cracking, no splintering, no swelling, no greying nor fading. A regular clean from time to time will suffice. Can be repaired without needing to be replaced.

Wood Plastic Composite: Like Naxan, it requires less maintenance than timber. Once broken, however, damage cannot be repaired. Full replacement must be undertaken.

Timber: Requires regular maintenance to preserve its appearance. Oil must be applied every 6-12 months to strengthen and protect it from weathering. If not well looked after, timber can lose its structural integrity and may even crack, splinter or rot. Overtime, UV rays will remove the natural colour pigments in the wood, creating a greying effect.

2. Environmental Impact

Naxan: Completely sustainable and environmentally friendly. Does not contain any recycled plastics and remains the less impactful material for the environment.

Wood Plastic Composite: As the name implies, the two main components found in this type of composite material are sawdust and recycled plastics, mainly from milk bottles and grocery bags. These plastics are not a renewable source.

Timber: Deforestation continues to be one of the severest problems today. Despite sourced from sustainably managed forests, the existence of illegal timber import sources makes it hard to discern the environmental impact.

3. Livability

Naxan: Does not splint. Does not get hot under the sun.

Wood Plastic Composite: WPC gets extremely hot when exposed to the sun for a prolonged period of time.

Timber: Pleasant to walk on if kept in good condition, otherwise it can lose its structural integrity and may even splinter. Timber regulates heat well.

4. Cost

Naxan: Despite its initial higher upfront cost, Naxan will not face additional fees from moisture issues (rotting, cupping, mold, etc.), regular oiling appliances, and so forth. Naxan can be processed the same way timber does, therefore damaged boards can be treated and not necessarily discarded.

Wood Plastic Composite: Full replacement needed when damaged.

Timber: Despite a lower initial cost, the need for regular maintenance alongside common issues like rotting, pest infestation, etc. can cause the cost to increase significantly.

A full comparison of features can be seen below.

Naxan stands as the best value for people who deeply care about the environment but still love the look and feel of natural timber. Due to its little-to-no maintenance requirements, Naxan is also one of the cheapest and easiest options in the long run.